A cross peen hammer is a versatile tool often used in metalworking and woodworking for shaping and striking. It features a flat face on one side and a wedge-shaped peen perpendicular to the handle, designed for precise work like riveting or bending metal.

The defining feature of a cross peen hammer is its wedge-shaped peen that allows controlled shaping and detail work, especially in tight spaces. This makes it valuable for tasks that require both force and accuracy, unlike a standard hammer which typically has two flat faces.

People who need a hammer for fine crafting or fabrication often choose the cross peen hammer because of its unique design. Understanding its specific use can improve the quality and ease of many detailed projects.

Understanding Cross Peen Hammers

A cross peen hammer features a distinct head shape and specific material choices that impact its functionality. Various types exist, each suited for particular tasks and industries.

Design and Structure

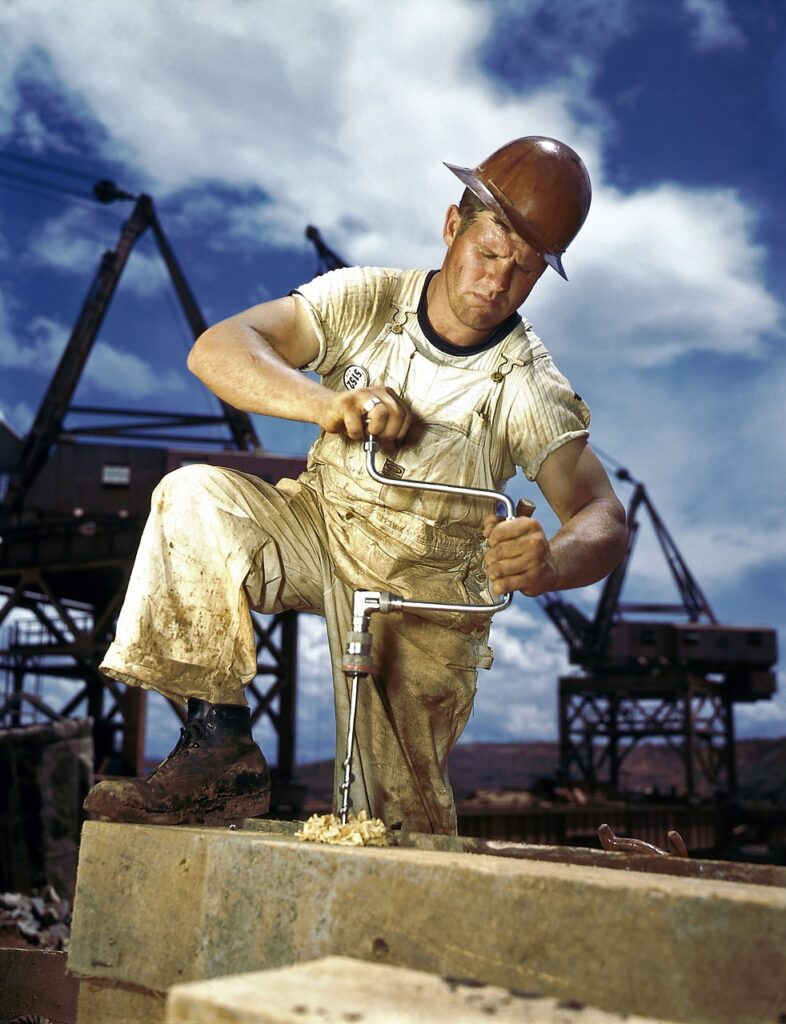

The cross peen hammer has a flat face on one side and a wedge-shaped peen perpendicular to the handle on the other. This design allows precise control for shaping metal, especially in blacksmithing and metalworking.

Handles typically range from 12 to 16 inches, made for one-hand use. The head is usually forged steel, securely attached to the handle through a wedge or epoxy. The peen helps stretch and shape metal, while the flat face drives nails or flattens surfaces.

Common Materials Used

Hammer heads are commonly made from high-carbon steel due to its hardness and durability. Some heads are heat-treated to improve toughness and resistance to wear.

Handles may be hardwood like hickory, valued for shock absorption and strength. Modern versions often use fiberglass or composite materials for better durability and vibration reduction.

The choice of materials affects the hammer’s weight and balance, optimizing it for various precision or heavy-duty metalworking tasks.

Types of Cross Peen Hammers

There are several specialized types based on size and application:

- Blacksmith’s Cross Peen: Heavier head, longer handle, designed for forging.

- Pattern Maker’s Hammer: Smaller, lighter, used for detailed shaping.

- Riveting Hammer: Features a slightly rounded peen for spreading rivets.

Each type is intended for specific metalworking needs, affecting control, force, and precision.

Applications and Best Practices

The cross peen hammer is designed to perform tasks requiring precision and control, particularly in shaping and forming metal. Proper use involves selecting the correct hammer type and applying techniques that maximize efficiency while minimizing damage and injury.

Key Uses in Metalworking

The cross peen hammer is primarily used for forging, shaping, and bending metal. Its narrow, wedge-shaped peen allows it to focus force on a small area, which is ideal for starting metal shaping by spreading or drawing out the material.

It is especially useful for creating grooves, tapering metal edges, and working on rivets or nails where precision is needed. Blacksmiths and metalworkers often use it to prepare surfaces before final finishing with other hammer types.

Choosing the Right Cross Peen Hammer

Selecting the appropriate size and weight depends on the workpiece and task. Lighter hammers (around 8-12 ounces) suit delicate work on thin metal sheets, while heavier ones (up to 2 pounds) are for thicker, tougher materials.

Handle material also affects control and comfort; wooden handles absorb shock well, while fiberglass offers durability with reduced vibration. Choosing a hammer with a properly balanced head enhances accuracy and reduces fatigue.

Safety Considerations

Users should always wear safety goggles to protect against flying metal shards. Gloves are recommended for grip and hand protection but should not limit tactile feedback.

Inspect the hammer regularly for head tightness and handle integrity to prevent accidents. Use controlled, measured strikes rather than excessive force, as this reduces the risk of slipping or metal deformation beyond the intended shape.